PET Hot fill bottle for condiments

Brand :None

Product origin :China

Delivery time :2024

Supply capacity :100000 pcs/week

Hot fill bottles are widely used in juice drinks and tea drinks. Hot fill bottles are widely used in juice drinks and tea drinks.

Hot fill process is a method of sterilizing the product at high temperature, at about 90 degrees into the bottle. This method uses the heat of the product to sterilize the bottle and lid, makes pet hot fill bottle keep high temperature for a long time, although it may cause certain damage to the taste and nutrition of the product, because PET bottle has good safety and economy, this process has been widely used in the mainstream beverage products such as fruit juice drinks and tea drinks. In addition, heating tank as a kind of cleaning equipment, its cleaning cleanliness is high, cleaning can be directly used in chemical fiber, blowing bottle PET bottle and other fields, is also used in old plastics and other industries as heating, cleaning treatment.

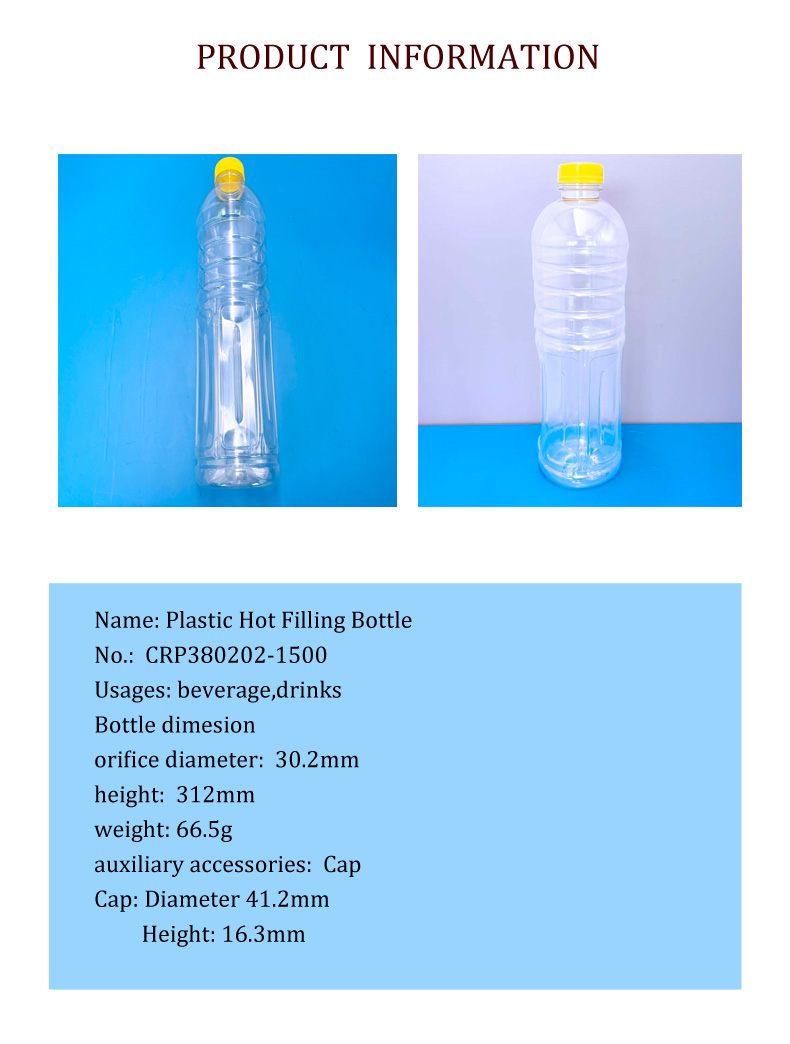

PET Hot Fill Bottle for Condiments

The Advantage Of Hot Fill Bottle

First, the special quality requirements ofpet hot fill bottle process.

pet hot fill bottle has good heat resistance. To overcome the influence of hydrothermal (high temperature) on the shape of the bottle: high temperature makes the bottle soft, high temperature and hot liquid create high pressure inside the bottle. It is better to control the volume shrinkage rate between 1% and 1.5% at high temperature (85℃ ~ 90℃).

Pet hot fill bottle should be able to withstand negative pressure. To overcome the negative pressure from PET bottle after liquid cooling; PET bottle wall shrinkage (flattening, negative pressure contraction of the bottle side wall deformation, oval phenomenon).

Second,hot fill bottle blowing method:

One-step method: The produced billet is crystallized by the crystallization furnace on the bottle mouth, and then directly made by high temperature mold. Advantages: High yield, easy to mass production. Disadvantages: The high temperature resistance is poor, the high temperature resistance decreases significantly with the extension of time, and the storage time can not be too long.

Two-step method: After the produced billet is crystallized on the mouth of PET bottle by the crystallization furnace, two sets of molds are used to complete the hot fill and blow mold. First, the first set of large-volume mold (low-temperature mold) is used to stretch and blow the bottle into a large-volume bottle; Then the PET bottle bottle for condiments is sent to the heating furnace for heat treatment (to eliminate the internal stress caused by tension); After heat treatment, bottle for condiments is sent to the hot mold (the mold of the final required volume size), and the bottle is further heat treated (improve the crystallinity of the bottle), set, and finally blown into the bottle of the desired shape and size. Advantages: The bottle has good high temperature resistance and long storage time. Disadvantages: Low yield is not suitable for large-scale production.

Samples for free when you want less than 20 pcs, freight collected,kindly noted you should pay 30-50 dollars for the sample fees....more